Optimising investment costs

In addition to efficiency and cost effectiveness, sustainability is also of key importance to purchasers of electrically-powered forklift truck systems. After all, purchasing costs are high, and users want future-proof technology that will not break after a short time or become outdated. The components of the three-part system - the forklift truck, traction battery and battery charging system - must therefore be fully compatible with one other, and must include high quality components, intelligent software and the ability to adapt flexibly to future developments.

Space-saving battery charging systems from Fronius avoid additional costs for the charging infrastructure

Fronius battery charging systems are light and compact. Compared to conventional 50 Hz devices and high-frequency technologies from other manufacturers, they are much lighter and smaller. This opens up many possibilities for the operator, as the battery charging systems can be mounted in space-saving locations such as on pillars or between loading ramps and roller shutters. The battery charging technology can thus be adapted to the spatial conditions available, thereby guaranteeing the best possible use of costly production and storage areas.

More efficient and higher-quality charging

A high-performance intralogistics operation involving electrically-powered forklift trucks requires a suitable charging infrastructure. However, the standard alternating voltage in Europe of 230 volts is not sufficient for every system. Converting the infrastructure to three-phase current with a voltage of 400 volts provides additional capacities, but also generates high costs.

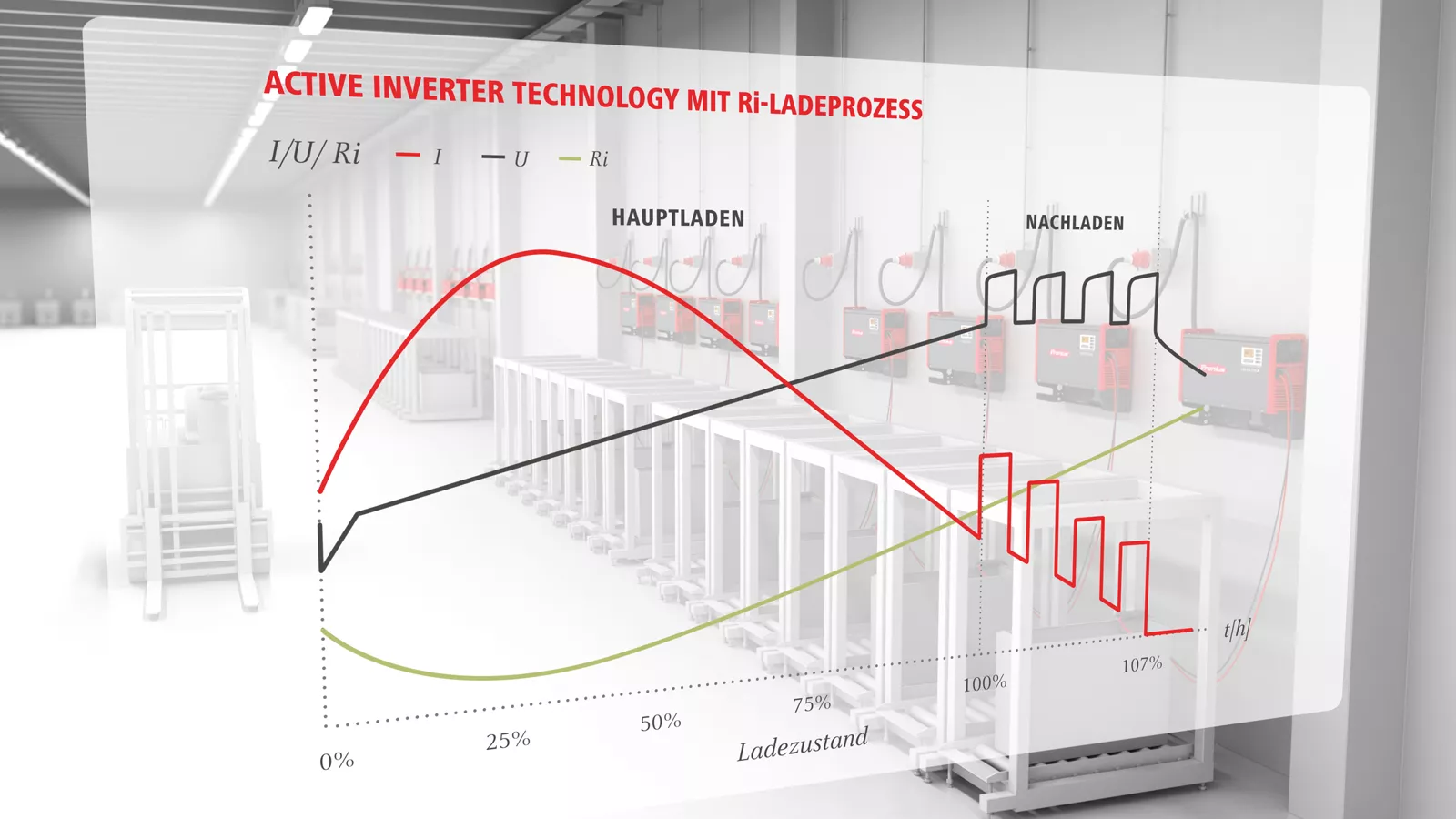

Fronius battery charging systems guarantee a much more efficient and higher-quality charge than other 50 Hz or high frequency battery charging systems. The innovative Ri charging process ensures optimum charging with minimum energy consumption depending on the age, state of charge and temperature of the battery. As a result, Fronius devices are often used with a 230 V mains voltage, whereas other systems would require a high voltage mains connection. This means that the operator can avoid expensive investments in the charging infrastructure whilst achieving the same output.

Long-lasting battery charging systems offer high investment security

Fronius battery charging systems are designed to have a long service life, right down to the smallest detail. Industrial-quality components and extensive testing far beyond existing standards ensure that each individual device meets the most stringent requirements, guaranteeing reliable and continuous operation even under extreme conditions.

With USB ports fitted to all devices in the Selectiva range, the operator can install software updates - such as characteristics for new battery technologies - quickly and easily. These can be downloaded from the Fronius website free of charge. The battery charging system is thus always up-do-date and the user enjoys the benefits of a future-proof, durable and sustainable system.

Eliminating electrolyte circulation when charging forklift truck batteries

When particularly high demands are placed on electrically-powered forklift trucks, an electrolyte circulation system (ECS) is often used to charge the traction batteries. This guarantees an ultra-gentle charging process and thus reduced warming of the battery. The charging time can be reduced considerably and the battery is ready for use again in a shorter space of time. There are disadvantages, however: purchasing a circulation pump attracts high costs and the systems are technically demanding, which can lead to problems during operation. An electrolyte circulation system is therefore not suitable for every application.

Fronius battery charging systems with the Ri charging process offer such a high-quality charge that in many cases the operator does not need an electrolyte circulation system. With the Fronius solution, the charging characteristic is adapted to the age, temperature and state of charge of the battery. Every single charging cycle is therefore unique and has its own characteristic, protecting the battery even during rapid and frequent charging and increasing its service life. Users can thus avoid the high costs involved in purchasing an electrolyte circulation system as well as uncertainties during operation, even in cases where the use of such a system with conventional battery charging technology is unavoidable.

High-quality battery charging technology from Fronius reduces servicing costs

Optimising operating costs is an important and ongoing task for operators of electrically-powered forklift trucks. Servicing costs are also a significant factor; the more time-consuming the servicing of forklift trucks, batteries and battery charging systems, the higher the costs. Users therefore prefer high quality, reliable solutions that can be repaired quickly and easily if required.

Fronius has placed a great deal of emphasis on quick and easy servicing in developing the latest generation of its Selectiva battery charging systems. These devices consist of three PC boards, which can be replaced in just a few minutes. Industrial-quality components and extensive testing far beyond existing standards also ensure that each individual Fronius battery charging system is reliable and long-lasting, thereby reducing maintenance and servicing costs to a minimum.