Special environments

In certain environments, it is even more crucial to choose the right battery charging technology. General factors such as dirt, dust and moisture, or particularly high or low ambient temperatures play a significant role, as well as operational factors, such as extremely long periods of use or strict safety and hygiene regulations. These specific requirements can only be met by high-quality battery charging systems that work reliably and cost-effectively, even under difficult conditions.

Battery charging technology for harsh environmental conditions

Dust, dirt and moisture, a poor quality or inconsistent grid, long periods of use and little to no breaks: there are many factors that can make the life of a battery charging system difficult. And this is where the wheat is truly separated from the chaff, as only high-quality systems designed for use under extreme conditions operate reliably in such an environment, and are therefore cost-effective in the long-term. Unsuitable battery charging technology results in high maintenance and unnecessary costs for frequent new purchases.

Fronius battery charging systems are known among experts for their reliable operation and long service life, even under the most extreme conditions. The reasons for this are high-quality manufacturing, customised accessories and well thought-out device properties. For example, the new generation of Selectiva battery charging systems feature a completely new ventilation system. The air flow for cooling the electronics is guided through the battery charging system via an air duct. In addition, each PC board in a Fronius device has a protective coating, which protects the electronics from dust, dirt and oxidation. An optional dust filter provides additional protection in particularly polluted environments.

Quality that far exceeds the norm

Our special testing methods ensure that every Fronius product meets the highest quality standards, is free from defects and continues to withstand tough conditions.Battery charging technology for high ambient temperatures

High ambient temperatures place enormous strain on traction batteries: the more they warm up, the more their useful life decreases. One particular issue is batteries arriving at the charging station when they are too hot, because high temperatures during the charging process damage the battery, reduce its service life and generate unnecessary costs.

The “delayed charging start” feature enables users to set a desired time for charging to start on almost all Selectiva battery charging systems. This gives the battery enough time to cool down before charging begins. Forklift truck operators can thus significantly extend the service life of their traction batteries without employing any additional technology.

Fronius can equip battery charging systems with the “temperature-controlled charging” feature on request. This means that a temperature sensor is installed between the cells in the cell case. When charging begins, the innovative Ri charging process records the temperature of the battery and adapts the charging characteristic accordingly. The user also has the opportunity to set limit values for the maximum temperature of the battery. If the temperature is close to exceeding this limit value, the battery charging system outputs a warning. If the critical temperature is exceeded, the device stops the charging process so that the battery does not become damaged. This increases the service life of the battery and makes the entire forklift truck system substantially more cost effective.

With the aid of the I-SPoT Viewer software tool, a user can analyse every charging process and optimise the process where necessary, for example by extending the charging time. A cooler and gentler charge is thus established, which in turn extends the service life of the battery.

Keeping a constant overview of all charging times

With the Fronius I-SPoT Viewer software, you get the perfect overview of your charging data and can further optimise your charging processes as necessary.

Battery charging technology for low ambient temperatures

From cold or deep-freeze warehouses to sheltered outdoor storage locations, forklift trucks - and thus their traction batteries - are often exposed to low ambient temperatures. This poses particular challenges for the operator, as the cold not only has a negative effect on the efficiency of the battery, but it also has a considerable impact on the charging process. If the temperature inside the battery is too low, the quality of the charge and the availability of the forklift truck system are reduced.

Fronius battery charging systems can be fitted with a “temperature-controlled charging” feature on request. This allows the battery charging system to record the temperature inside the battery and adapt the final charging voltage accordingly. If the temperature is too low, charging can also be delayed until the battery is warm enough. The result is a constantly optimised charge that enables the user to fully exploit the capacity of the battery.

Alternatively, the operator can adapt the charging characteristic on the device easily and flexibly depending on the ambient temperature. This improves the quality of the charging process and guarantees efficient batteries.

Reliable and efficient, even at ice-cold temperatures

Logistics service provider Frigologo specialises in the temperature-controlled storage and transport of foodstuffs. Frigologo relies on more than 100 battery-powered forklift trucks for a seamless flow of goods and materials, yet temperatures as low as -24 degrees Celsius pose huge challenges to this important fleet. In order to charge the traction batteries safely, reliably and efficiently under these extreme conditions, Frigologo uses innovative technology from Fronius.

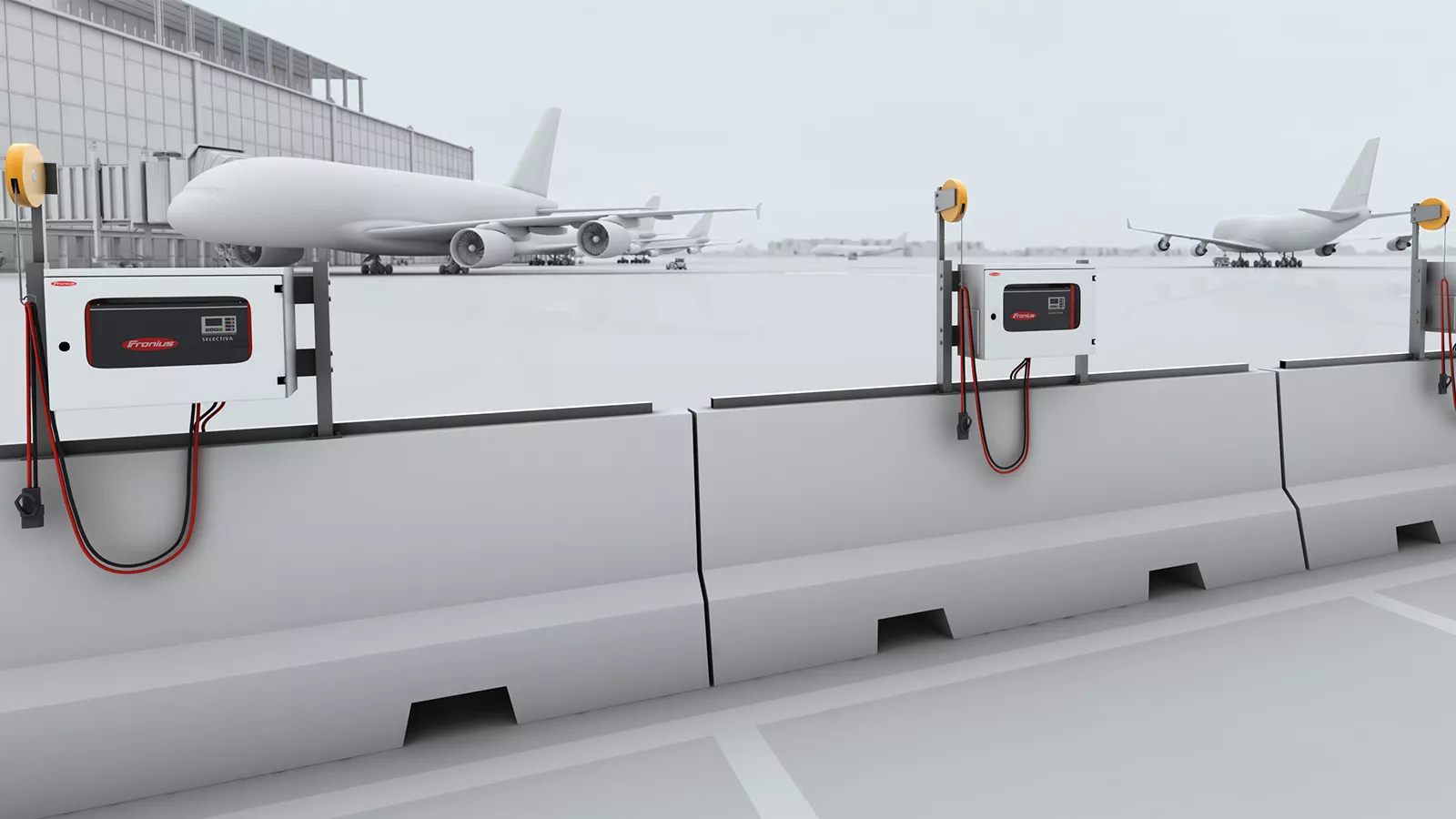

Battery charging systems for use in clean rooms

Be it in the pharmaceuticals and food production industries, or at the airport, electrically-powered forklift trucks are often used in environments with the highest safety and hygiene standards. Special battery charging technology is therefore required, as the oxyhydrogen produced when charging lead batteries can quickly lead to problems in clean rooms - for instance, if it comes into contact with sensitive or reactive substances. Consequences include risks to employees and goods, or violation of standards and clean room regulations.

For this reason, users in clean rooms often work with closed gel batteries. These have the advantage of producing next to no oxyhydrogen, thus minimising the risk of explosions. However, the procurement costs of these batteries are extremely high.

Fronius battery charging systems have a special gel charging characteristic that reduces harmful overcharging of the battery to a minimum. The cooler temperature during charging ensures an extended battery life and considerably lower procurement costs for the gel batteries.

In addition, Fronius is an expert partner in equipping standards-compliant battery charging rooms and stations. Specially trained employees support the user right from the planning phase and ensure that the systems meet all of the fire and explosion protection regulations. Fronius also offers a comprehensive product portfolio for adapting battery charging rooms and stations to individual circumstances and requirements.