Fronius Product Highlights

FABTECH 2024

Manual welding

Artis

Your craftsmanship, our technology

Our main focus was to ensure that the mobile TIG welding machine makes the best possible use of the input voltage. This not only makes the Artis energy-efficient, but also extremely reliable and productive, which will ultimately make your welding experience more enjoyable!

Ignis

The best result with every power grid

This robust MMA welding machine always provides perfect results, even with unstable grids, generator-powered operation, or over a wide operating radius. It makes the Ignis the perfect companion—especially on construction sites, for repair and maintenance work in industry and agriculture, and in any home workshop.

iWave Multiprocess PRO

Full freedom

It’s all within your grasp: a single system to cover every welding process – from TIG and MIG/MAG through to MMA – and every process variant. The right solution for today, tomorrow, and beyond: with iWave Multiprocess PRO, you can easily master the full array of welding challenges.

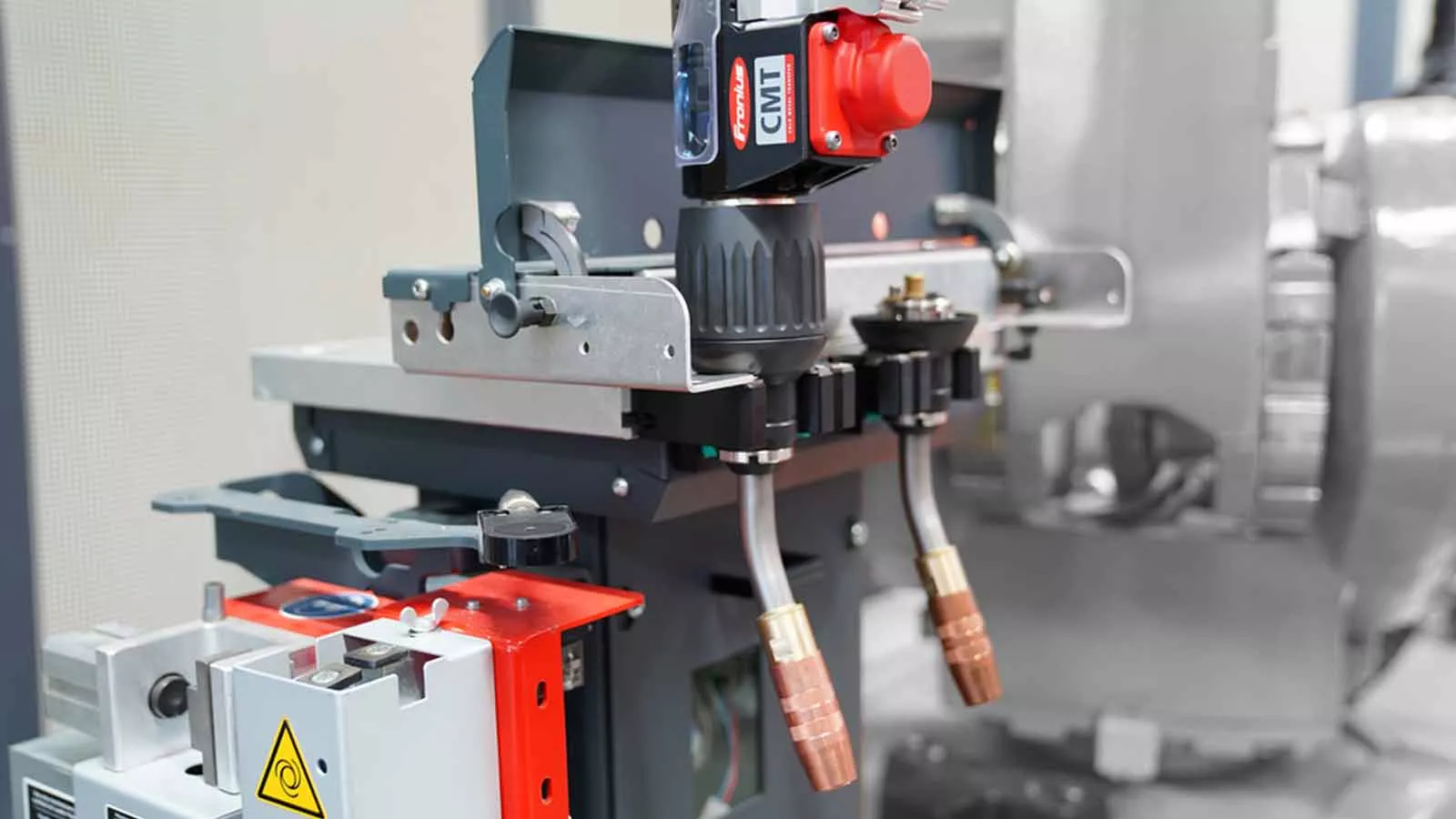

Dual Wire Feeder - WF 25i Dual

Two welding torches, two wirespools but just one welding system

Greater productivity and potential savings: with the WF 25i Dual, you always have the right wire at hand, regardless of whether there are two different filler metals or wire diameters. So there’s no need to exchange wirespools, wear parts, or the welding torch.

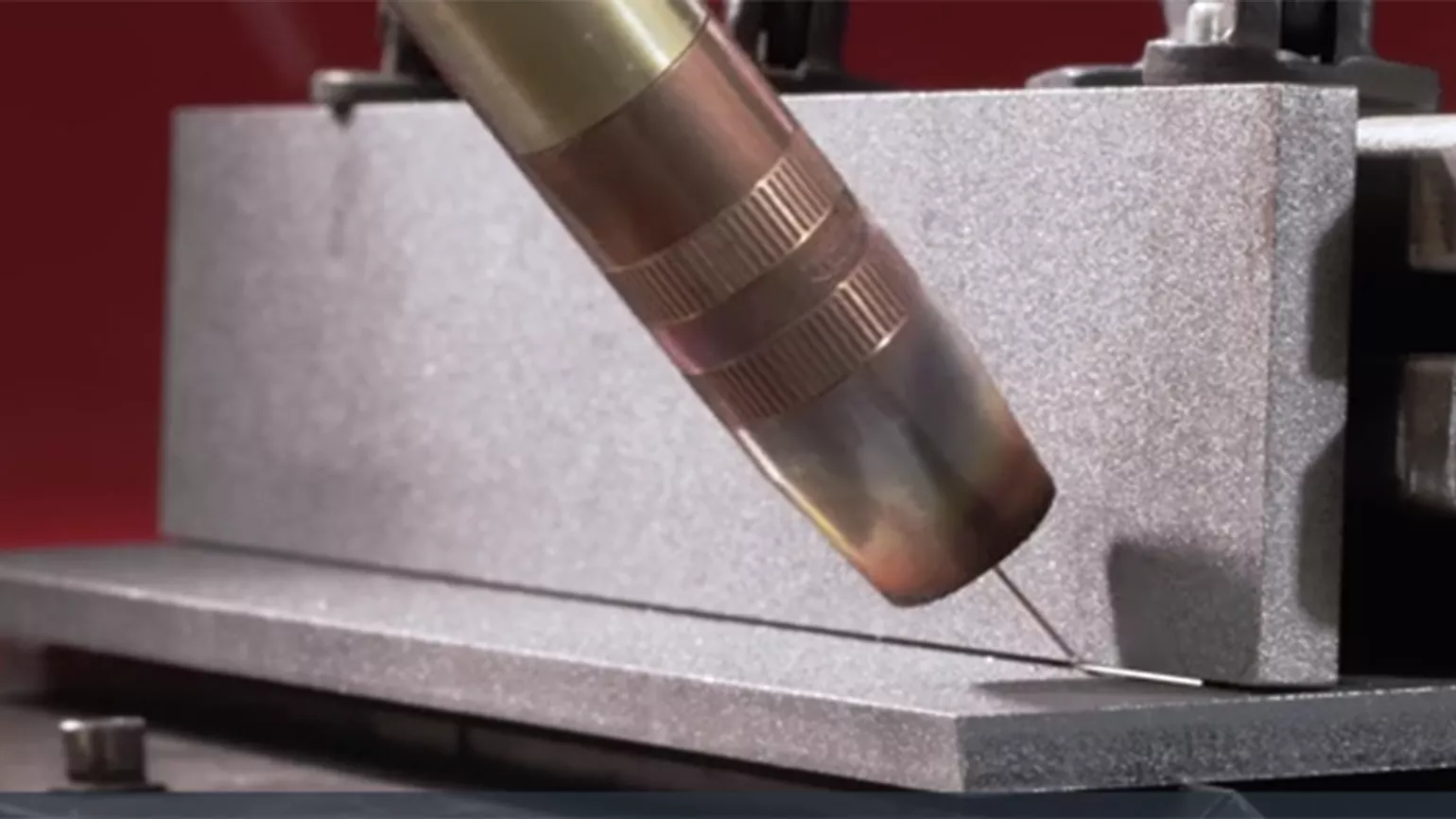

TIG Dynamic Wire

Cold wire TIG welding – smart and simple

With new TIG DynamicWire welding package for the iWave welding machines, even amateurs can achieve perfect TIG welds with ease. Compared to a conventional continuous wire feed in cold wire systems, TIG DynamicWire actively adjusts the wire speed to the welding behavior, torch position, and current conditions.

WeldCube Navigator

WeldCube Navigator - Real-time feedback solution for welding specialists

High-quality welds are essential for many products. Faulty or missed welded joints lead to high manufacturing costs. The earlier these faults are identified in the manufacturing process, the quicker it is to respond to them. The WeldCube Navigator software solution supports you step by step in production. Using the guidance and job pre-setting functions of the WeldCube Navigator can shorten the training and familiarization period for new welding specialists and thus minimize the risk of errors.

Health & Safety

Exento

Mobile welding fume extraction

Exento extraction devices, combined with extraction arms or fume extraction torches, are used to extract welding fumes and—depending on the model—are suitable for temporary and permanent jobs. Their high mobility and the 360-degree usage radius make them particularly flexible and the ideal partner for changing workplaces. Welding fume exposure for all of the welding personnel is therefore significantly lower.

Fume extraction torches

Precision extraction directly where welding fumes are produced

Fume extraction torches and extraction sets eliminate welding fumes where they are produced. Welding fumes are detected before they are able to spread, which not only protects the welder, but also everyone in the vicinity.

Vision protection

Crystal clear view

Detailed and high-contrast: In addition to its wide field of vision, the Vizor Crystal features unique glare protection technology. In light conditions, you can perceive color almost as clearly as you would through a clear glass window. In darkness, welders have a detailed and high-contrast view of the weld pool, with unprecedented clarity.

Robotic and automated welding

CWC-S Cobot Welding Cell

Generate sustainable profits - even for SME

The CWC-S offers a high level of flexibility for welding different components - from batch size 1 to small series. Operation can be learned in just a few hours and no knowledge of programming is required. Trainees can learn how to use the CWC-S in no time, allowing them to take much of the strain off your specialist welders.

Assistance systems for robotic efficiency

Support through assistance systems for welding robots

One particularly important factor in robotic welding is increasing the efficiency and quality of welding tasks.Fronius offers technologies for this that help save time and money.

Robotic torches and peripherals

MIG welding torches for robotic applications

From difficult to access components to remote job sites: Fronius welding torches are designed to cover a broad range of applications. Different torch necks of different lengths and angles make life easier. Welders can count on the flexibility they need with Fronius – guaranteed.