Viñolas Metall

New welding solutions for Industry 5.0

Viñolas Metall is a Spanish family business working in the metal and boiler construction segments. The company has a broad range of customers from a variety industries, including swimming pool accessories, water treatment, machine, plant and tool construction, and railroad and aircraft construction. Viñolas recently invested in Industry 5.0 solutions for application in areas including welding.

What’s your welding challenge?

Viñolas Metall

Sites:

2

Employees:

48

Manufacture of:

Metal structures for a range of sectors

Boilers

Fronius products used:

FlexArc robotic welding cell with reversible positioner and TPS 400i CMT

iWave Pro AC/DC

TransTig 5000

TransTig 2200

Process application:

MIG/MAG

CMT (Cold Metal Transfer)

TIG

ArcTig (keyhole welding)

When we need to weld identical parts to the highest quality with unbeatable reproducibility, we turn to Fronius because they always have the solution we’re looking for.

The challenge

Viñolas welds beams for swimming pool enclosures from chrome-nickel steels 304 and 316. When manufacturing these series components—which are put to use in corrosive environments—it is essential to take industry specifications and welding standards into account. Welding autonomy, high welding quality, and guaranteed reproducibility were therefore key when Viñolas went looking for a suitable system.

The solution

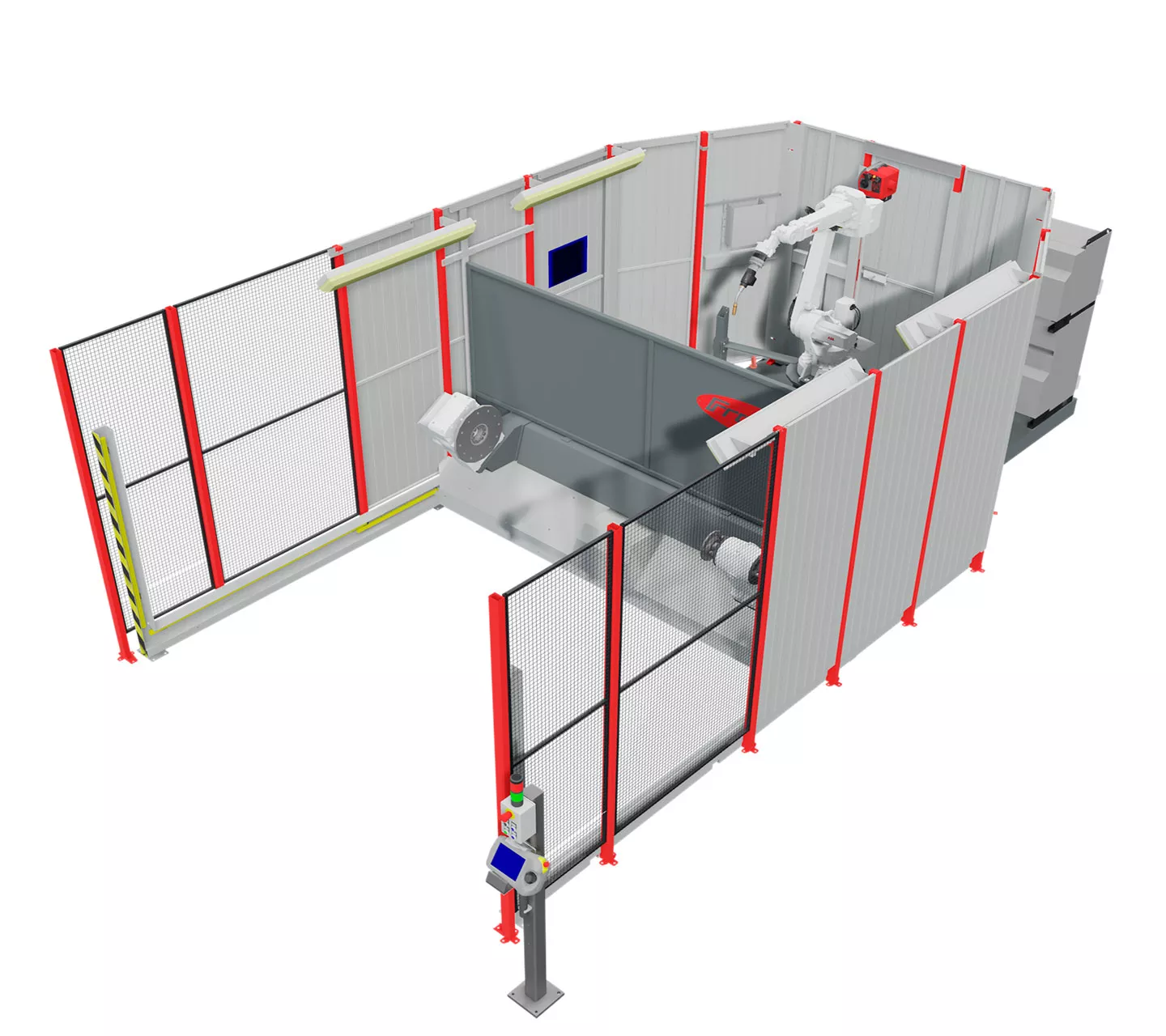

The welding solution consists of a robotic welding cell equipped with TPS 400i CMT welding technology and a reversible positioner, which has two vertical turntables on a horizontal axis on both sides. Once one side of the positioner is loaded, the components rotate into the welding cell and are joined in a single cycle. On the other side, the finished welded components can be removed and new ones positioned, thereby saving valuable cycle time. When performing automated and manual tasks where rapid process changes between MIG/MAG and TIG are required, Viñolas turns to the iWave Pro 400i AC/DC multiprocess welding machines.