Welding in the Food and Beverage Industry

Pulling out all the stops against germs and bacteria

Welding in this sector is all about hygiene

Germs and bacteria have no business being present in the food industry. For this reason, surfaces and welded joints must be as smooth and as flat as possible. Weld seams that come into contact with liquids must always be ground flush. In addition, container walls and pipes must not exhibit any spatter or temper coloration after welding. Industry and regional or international standards are authoritative.

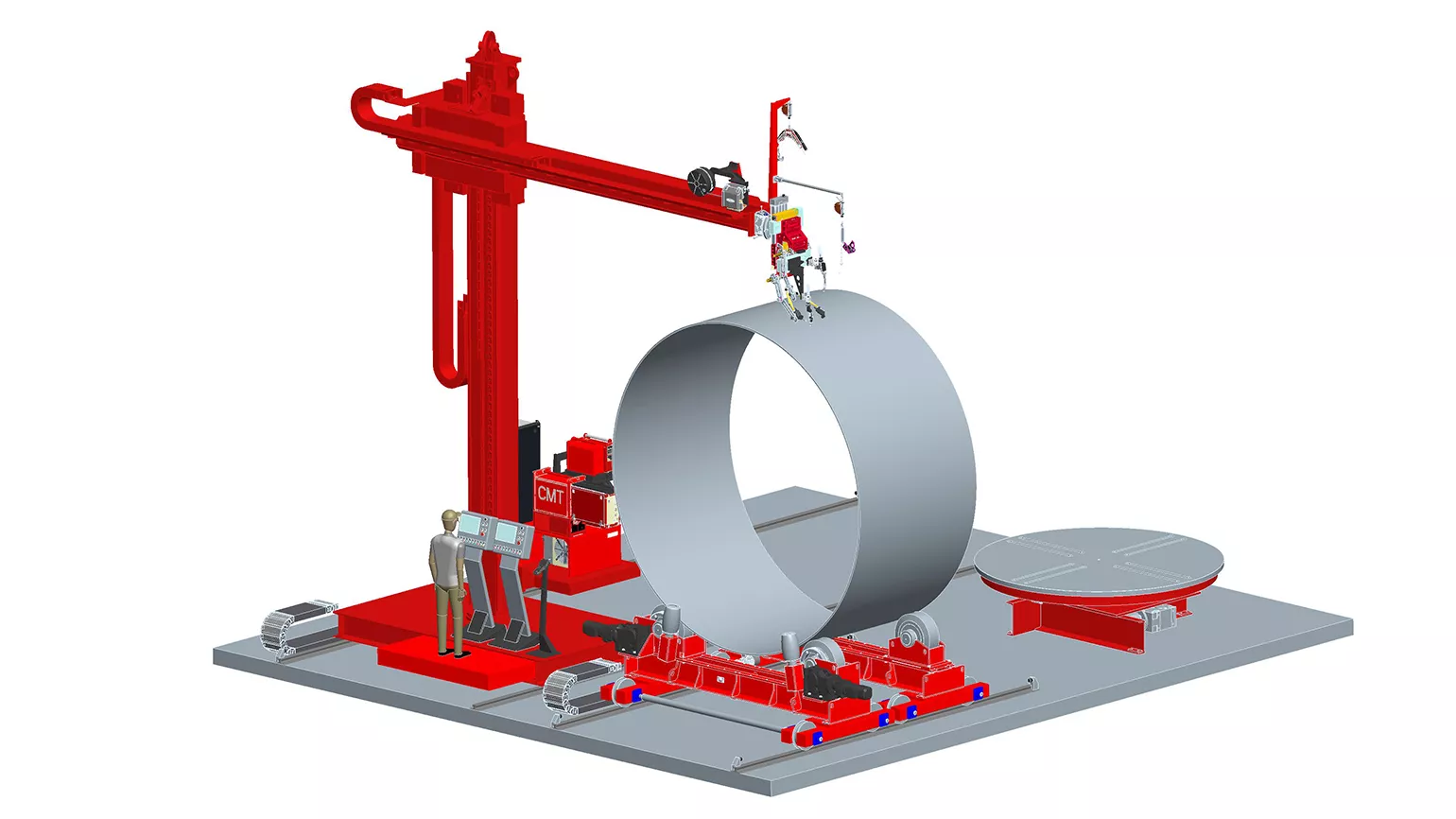

Mechanized welding in container construction

Typical seam connections

Longitudinal seam welding systems

For welding container shells

FCP 2100-2 seam welder

FCP 2100-2 seam welder with intuitive HMI system controls, TIG, ArcTig, Plasma

FCP 6100-2S seam welder

FCP 6100-2S seam welder with intuitive HMI system controls, TIG, ArcTig, Plasma

Circumferential welding systems

For welding container shells

Circumferential welding systems for joining container shells in flat position (PA)

Intuitive HMI system controls, remote control, and ArcView camera system for monitoring the weld seam.

Welding processes: TIG, ArcTig, Plasma

Circumferential welding systems for joining container shells in horizontal-vertical position (PC)

Intuitive HMI system controls, remote control, and ArcView camera system for monitoring the weld seam.

Welding processes: TIG, ArcTig, Plasma

Circumferential welding systems for joining container shells and container bases

FCW compact welding system

Robust welding system with intuitive HMI system controls and remote control. Ideal for small and medium-sized businesses.

Welding processes: TIG, ArcTig, Plasma

FCW 650 circumferential welding systems

Mobile welding system incl. FCU-20 system controls. Ideal for small and medium-sized businesses.

Welding processes: TIG

Circumferential welding systems for welding different components, e.g., agitator mixer

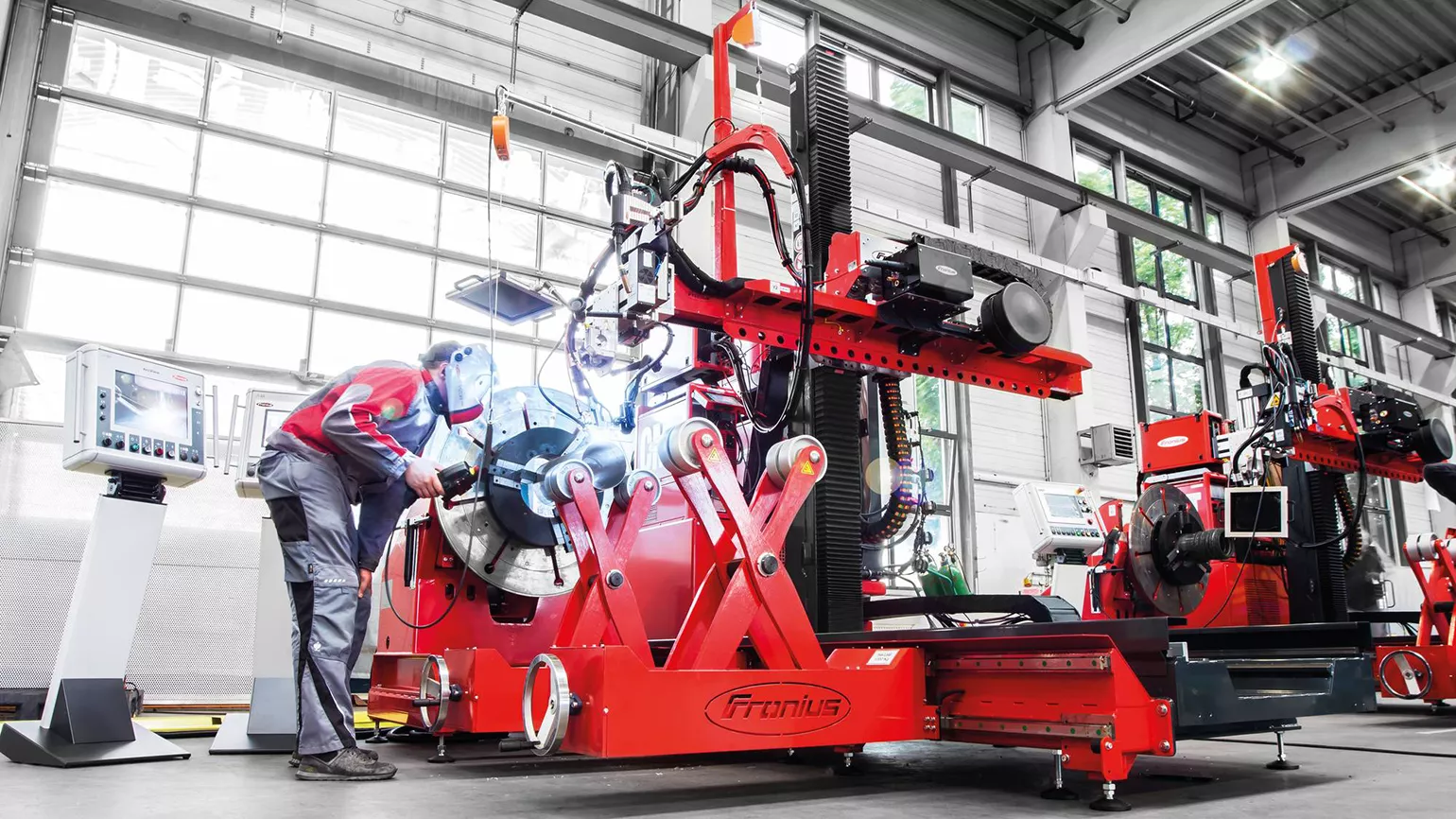

FMW multi welding system

Welding system for circumferential and longitudinal seam welding of different components. Intuitive HMI system controls, remote control, and ArcView camera system for monitoring the weld seam.

Welding processes: TIG, plasma

Agitator for cheesemaking

Let´s get connected!

Manual welding in container construction

Typical applications

Welding systems

for manual welding in container construction

Mechanized welding in pipeline construction

Typical seam connections

Orbital welding systems

Mechanized orbital welding systems for joining pipes and flanges

FCH closed orbital welding heads

FOH open orbital welding heads